1. Objective

The range and quantity of hazardous substances used in [Project/Site Name] make it impossible to provide a single all-encompassing plan for dealing with chemical/biological incidents. The Project QHSE Engineer, Project Manager, Project Engineer, supervisors, and each member of the MEP-FM team are expected to deal with minor spills (see definitions, below) occurring in their area. This requires pre-planning and training/rehearsal.

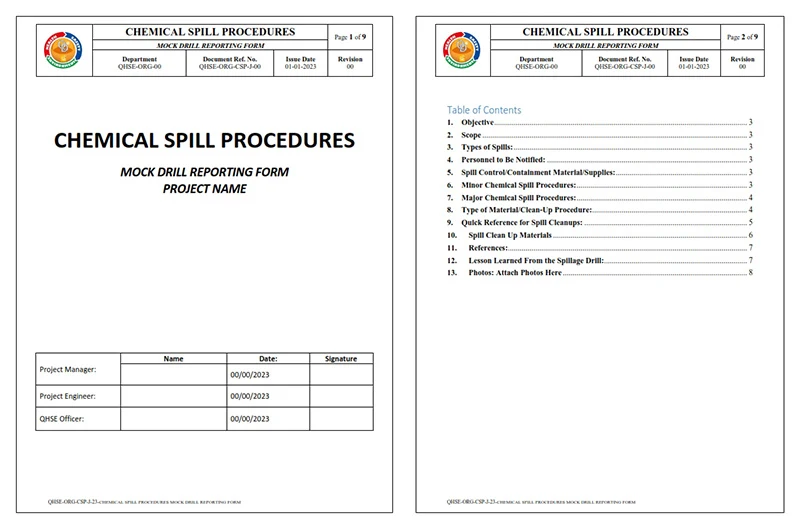

2. Scope

This “CHEMICAL SPILL PROCEDURES MOCK DRILL REPORTING FORM” document provides guidelines for developing an individualized spill response plan and Reporting.

3. Types of Spills:

A. Minor Spills are those which can be handled by the MEP-FM team.

B. Major Spills are those which require notification of or assistance from other agencies e.g., Environment Agency A spill automatically becomes "major" in the following instances:

- There is a fire, or the threat of fire, outside of a controlled space (fume hood).

- There is a personnel injury or exposure likely to require medical assistance.

- The spill involves unknown or highly reactive material.

- There is a release of a toxic or flammable gas outside of a controlled space.

- Personnel to Be Notified:

Project Manager:

Project Engineer:

Primary Investigator/HSE:

Facility/Client’s Representative:

Police:

5. Spill Control/Containment Material/Supplies:

For the project [Project/Site Name] for a recommended list of materials/supplies).

6. Minor Chemical Spill Procedures:

- Alert people in the immediate area of the spill.

- Avoid breathing vapors from spills.

- Put on protective equipment, including safety goggles, suitable gloves, and a long-sleeved lab coat.

- Confine spill to a small area.

- Use appropriate materials to neutralize and absorb inorganic acids and bases.

- For other liquids, absorb spill with vermiculite, dry sand, or adsorbent pads.

- For solid spills. Cover the spill with a slightly damp paper towel to avoid creating a cloud of dust, Push the material into a dustpan or other instrument using the towel- do not use a broom/dust brush.

- Collect material, used adsorbents/neutralizing agents, etc. in a polyethylene bucket or bag.

- Call EH&S (Project QHSE Engineer) to arrange for the collection and disposal of spill residue.

7. Major Chemical Spill Procedures:

- Attend to injured or contaminated persons and remove them from exposure.

- Alert people in the area to evacuate. If danger is believed sufficient - pull the fire alarm and evacuate the building.

- If spill material is flammable, turn off ignition and heat sources if that can be done safely.

- Close doors to the affected area.

- Call Police (000. Provide as much of the following as is known.

- Contact Environment Agency. (+000 0 000 0000)

- What chemical(s) are involved?

- How much was spilled?

- Where the spill is located.

- Nature of any injuries.

- What control measures have been taken?

- Your name and phone number (or where you will be located).

- Meet responders.

8. Type of Material/Clean-Up Procedure:

The table below provides a synopsis of the type of chemicals that may be spilled and recommended clean-up materials. This list should be amended to add any chemicals requiring special procedures. As always, the SDS on the particular chemical is a preferable reference. If you choose to purchase, pre-packaged, commercially available spill kits, the clean-up procedures should be modified to reflect specifics, e.g., Acid Spills: Use container "A" from spill supplies following directions on the package.

9. Chemical Spilled & Clean-Up Procedures

Acids, organic: Apply sodium bicarbonate. Adsorb with a spill pillow or vermiculite.

carbonate/calcium oxide. Adsorb with a spill pillow or vermiculite. NOTE: Hydrofluoric acid is an exception to the general practice, see below.

Acid Chlorides: Do not use water. Absorb with sand or sodium bicarbonate.

Aldehydes: Absorb with a spill pillow or vermiculite.

Aliphatic Amines: Apply sodium bisulfite. Adsorb with a spill pillow or vermiculite.

Aromatic Amines: Absorb with a spill pillow or vermiculite. Avoid skin contact or inhalation.

Aromatic Halogenated Amines: Absorb with a spill pillow or vermiculite. Avoid skin contact or inhalation.

Asides: Absorb with a spill pillow or vermiculite. Neutralize with 10% ceric ammonium nitrate solution.

Bases (caustic alkalis): Neutralize with acid, citric acid, or commercial chemical neutralizers. Absorb with a spill pillow or vermiculite.

Carbon Disulfide: Adsorb with a spill pillow or vermiculite.

Chlorohydrin's: Absorb with a spill pillow or vermiculite. Avoid skin contact or inhalation.

Cyanides: Cover solids with a damp paper towel and push them onto a dustpan or use a HEPA filter vacuum to collect them. Absorb liquids with a spill pillow or vermiculite.

Halides, organic or inorganic: Apply sodium bicarbonate.

Halogenated Hydrocarbons: Absorb with spill pillows or vermiculite.

Hydrazine: Avoid organic matter. Apply "slaked lime". Adsorb with a spill pillow or vermiculite.

Hydrofluoric Acid: Adsorb with calcium carbonate (limestone) or lime (calcium oxide) rather than sodium bicarbonate. Using sodium bicarbonate will lead to the formation of sodium fluoride, which is considerably more toxic than calcium fluoride. Be careful in the use of spill pillows used to adsorb the acid. Some pillows contain silicates that are incompatible with hydrofluoric acid.

Inorganic Salt Solutions: Apply soda ash

Mercaptans/Organic Sulfides: Neutralize with calcium hypochlorite solution. Absorb with a spill pillow or vermiculite.

Nitriles: Sweep up solids. Absorb liquids with spill pillows or vermiculite.

Nanoparticles: Pick up particles with a HEPA or ULPA-filtered vacuum.

Nitro compounds/Organic Nitriles: Absorb with spill pillow or vermiculite. Avoid skin contact or inhalation.

Oxidizing Agents: Apply sodium bisulfite.

Peroxides: Absorb with a spill pillow or vermiculite.

Phosphates, organic and related: Absorb with a spill pillow or vermiculite.

Reducing Substances: Apply soda ash or sodium bicarbonate.

10. Spill Clean-Up Materials

Each [COMPANY NAME] Site/Project team for [Project/Site Name], should have at least enough material to handle a spill of 1 LT/1 KG (or the largest container in inventory) or all chemicals on-hand. In addition, each facility, especially those with floor drains should have spill socks, pillows, pads, or bulk absorbent to contain spilled material.

Kits may be built from raw materials, see the table in the basic document for type materials.

Purchased as individual items or as composite kits from suppliers or QHSE personnel.

The table below (courtesy of Bio-Engineering) are the contents of a spill kit for a typical laboratory.

11. References:

[Write your State or Country’s References Here]

Environment Agency

Hazardous Materials

Waste Management

12. Lesson Learned from the Spillage Drill:

Although many spills may appear routine, each is unique in location, environmental conditions, and behavior. Furthermore, responder capability, response technology, norms, expectations, and political climate are always in flux and will continue to change with time. There are always ways to improve and adapt. Because of the reactive and continuous nature of emergency response work the [COMPANY NAME] has found it challenging to establish an expeditious, yet still meaningful procedure in which to capture lessons for each response, and even more difficult to evaluate and implement those lessons. As with any change, it took time to adopt this method (adopted during the spillage drill), yet through the dedication of the [COMPANY NAME], lesson-learned reports, and an annual Operating Plan, this approach has been successful. The General International staff sees the benefits come back around during improved training, equipment, skills, preparedness, and responses. The use of this process is now standard and expected. It has increased confidence in staff that the organization can capture and address both small and significant issues, the courage and dedication to evaluate and implement changes and become a progressive learning organization. Through the use of this system, the [COMPANY NAME] 's response products have been improved, the [COMPANY NAME]’s responders are more aware of lessons learned, anticipate potential situations that could lead to known outcomes, make conscious decisions to choose wiser courses, and engage in spill response with improved effectiveness and efficiency.

Note:

*No use of hazardous chemical storage, handling, and use is in the scope of work for [COMPANY NAME] at [Project/Site Name] project.

13. Photos: Attach Photos Here

SOURCES:

https://enhs.uark.edu/_resources/documents/spill-cleanup-quick-reference.pdf

https://www.palmbeachstate.edu/safety/Documents/ChemicalSpillResponsePlan.pdf

https://safety.charlotte.edu/sites/safety.charlotte.edu/files/media/CHEMICAL-SPILL-PROCEDURES.pdf

0 Comments